Protect Your Pressure Instruments from Heat

Excessive exposure to heat can cause your pressure gauges and pressure transmitters to read inaccurately. Most Bourdon tube pressure gauges will exhibit an additional 0.4% error in span for every 18°F above reference conditions (68°F). So if your instrument is running at a temperature of 200°F that’s an additional 3% error in reading added to the manufacturer’s stated accuracy.

Keep your instruments accurate on critical applications by using diaphragm seals and properly selected additional heat dissipating elements.

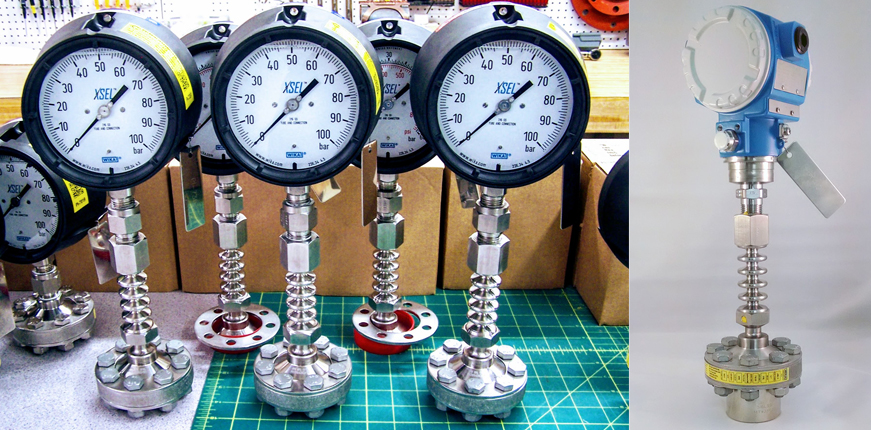

Keep your instruments accurate on critical applications by using diaphragm seals and properly selected additional heat dissipating elements. Pictured here we have unit shipping today for a customer that consists of a Wika 232.34 Process Gauge with an 8″ cooling element and a Wika L990.10 Diaphragm seal with high pressure bolting and a silver plated inconel X-750 process gasket, and a special high temperature silicone system fill. This unit can run at process temperatures up to 750°F without any significant loss of accuracy.

Cooling elements are offered in both 4″ and the 8″ design. The featured image at the top of this article shows both pressure gauges and transmitters utilizing the 4″ finned cooling element. The 4″ cooling element paired with the proper diaphragm seal can handle direct mount process temperatures up to 500°F and maintain ambient temperatures at the connection of the instrument . We stock this in both 1/4″ NPT and 1/2″ NPT configurations and can pair with a stock diaphragm seal offering and can ship in 1-2 days after receipt of order.

At Colonial Instruments we can help you select the proper instrumentation to assure you get accurate measurements.