Pressure Calibration

PRESSURE CALIBRATION

Colonial instruments offers NIST or SI unit traceable calibration of pressure instruments From 5” water up to 15,000 psig. Typical turnaround times run about 1 week, however We can offer expedited service, in some cases, same day turn around.

SERVICE DETAILS

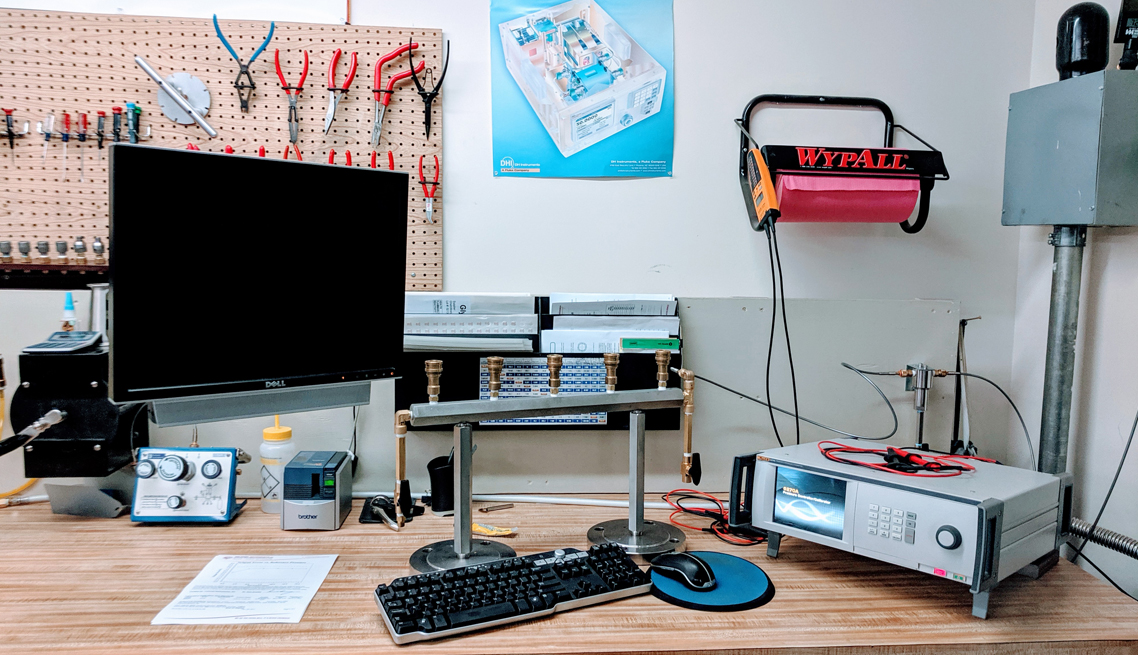

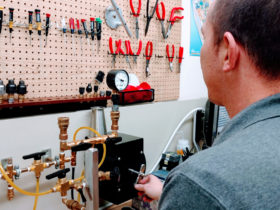

We use state of the art Test standards, which are sent out at regular intervals for calibration to ensure the accuracy of our lab. We utilize a fluke PPC4 Pressure Controller/Calibrator for a total accuracy of ±0.01% of Span on pressures from 5 psig up to 1,000 psig or a high accuracy Fluke 6270a Pressure Calibrator for ranges up to 300psi. High accuracy low pressure manometers for a total Accuracy of ±0.1% of span on pressures from 5” water up to 250” water. High accuracy Fluke/Martel Beta Gauge PI reference class digital gauges for a total accuracy of 0.05% of span on pressure from 1,000 psig up to 15,000 psig. Below you will find a listing of our primary metrology standards.

MISSION STATEMENT

Unlike many other “Calibration” labs, at Colonial Instruments we actually do calibrate analog pressure instruments and do repair work. We have found that many times other labs simply test an instrument, and when it does not pass, they provide the customer with a “failed” test and return the instrument as is and charge the same amount they would if the instrument had passed. We spend the time to take the instrument apart and use the span and linearity adjustments to calibrate the instrument and return it to the manufacturer’s stated accuracy whenever possible. If an instrument is not repairable, we will provide a quotation on a new replacement instrument, which we typically would have in stock, and we do not charge for the failed instrument. We can also repair instruments that have small problems like broken windows, damaged pointers, etc.

We take the time, when an instrument is sent in for calibration, to clean up the instrument (remove an Teflon tape from connections, wire brush any debris from pressure connections, do a general cleaning of the instrument, including case and window, etc.) All of this is included in the calibration charge. On analog pressure gauges we do a minimum 5 point calibration certificate traceable to NIST or equivalent SI unit. We also offer pressure calibration on transmitters and digital pressure gauges, manometers, etc. We have HART capabilities to scale or custom configure transmitters with HART communication protocol. Our custom dial capabilities also allow us to design and print custom artwork that can be applied to an instrument (additional charges may apply), if a customer so desires their logo, or a special scale on and instrument, an also wants a traceable calibration certificate.

We provide both re-calibration of existing instruments and calibration on new instruments. Since we stock a wide variety of pressure instruments, we can offer in stock options for customers that may need a fast delivery. Give us a call anytime with any questions or inquiries that you may have. One of our experienced calibration technicians or sales persons would be happy to help.