Custom Product Assemblies

CUSTOM PRODUCT ASSEMBLIES

At Colonial Instruments we always try to go the extra mile, because as you know, it’s never crowded. That includes working with customers to find out side of the box solutions to their problems by designing and fabricating customized product assemblies.

SERVICE DETAILS

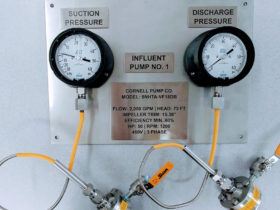

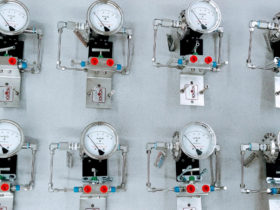

We can work with you, your client or the project engineer and come up with a product solution for the application at hand. Our experienced Process Instrumentation Specialist will help design and our shop fabricate what you need. We’ve done everything from customized gauge mounting panels, custom mounted DP gauge and manifold assemblies with tubing, custom “Tridicator” and gauge and thermometer assemblies, and much more. Give us a call next time you come across the need for instrumentation that may not be a standard “off the shelf” item, we may just able to come up with a solution.